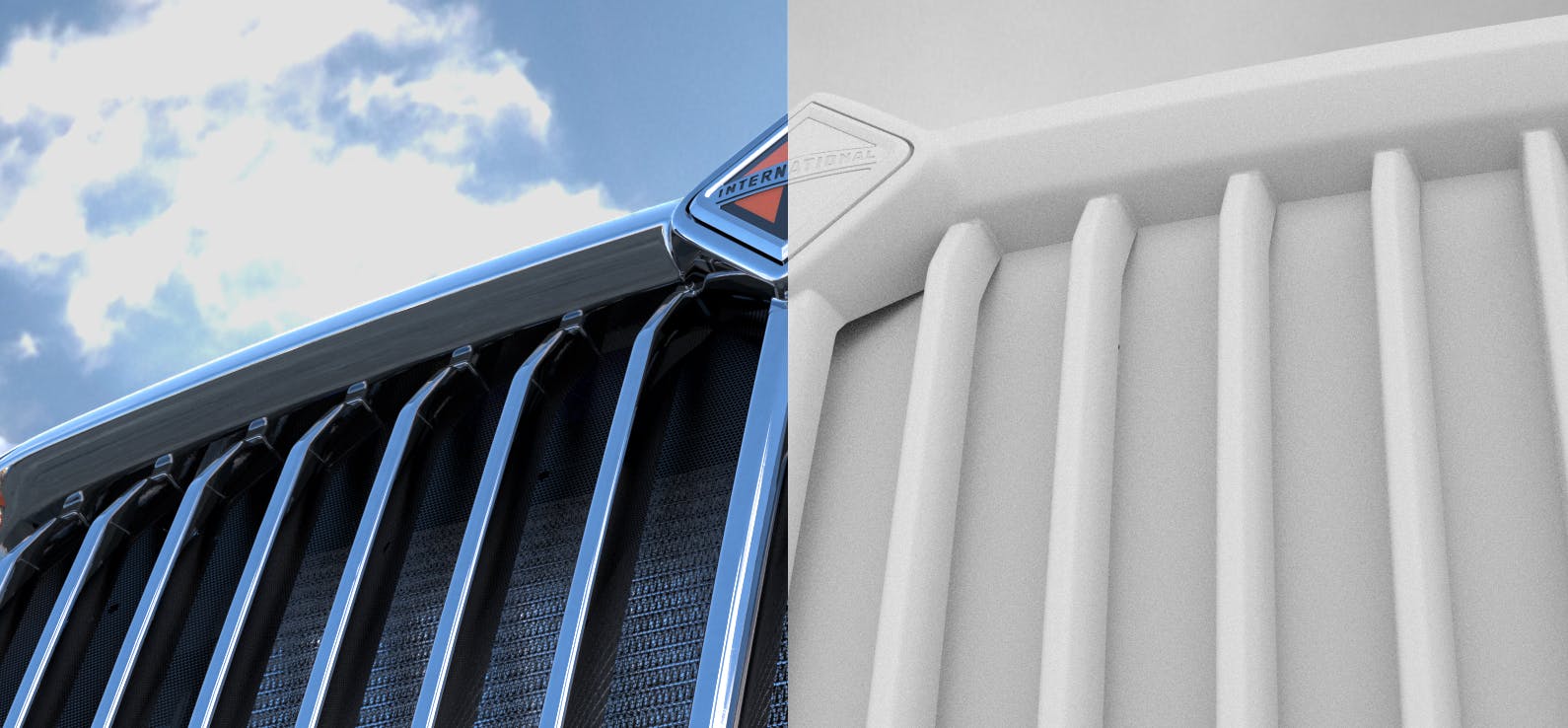

International Truck //

Engineered to evolve.

How we built a CG production pipeline designed to maximize production efficiency, that keeps pace with cutting edge products that are always moving ahead.

Product Modifications //

Updating only what needs to be updated

Product modifications can be difficult to predict and manage over a product's lifetime. At Clutch, we strive to build long lasting parternships, which means we need to design our tech infrastructure to support products over their lifetime, not just for the immediate project or deliverable requirement. For International Truck, we track and organize our CG models not by vehicle, but by each part down to the screws. Doing so allows us to receive instructions on product modifications, understand and identify what parts are changing and what parts are staying the same, and make updates to only those parts.

Product Consistency //

Engineering accurate models across a range of deliverables

Another advantage of a part-centric vs. vehicle-centric database is that when models are utilized across deliverables, we can be confident that we have 100% accuracy to the latest engineering approved model. CG teams are made up of many individuals working together and a centralized parts database ensures that any update made for one project, is automatically made for the next artist when they place the model in their scene. This degree of organization isn’t necessary when working on a single project with a dedicate team, but when supporting a product for its lifetime, the time savings on engineering review revisions for both Clutch and our partners is substantial.

Asset Compatibility //

Making sure the engineering accurate model is forwards and backwards compatible.

Lifetime product support often means our partners would like to revisit a previous deliverable and create something new out of it. A parts centric database ensures that whenever a scene was created, regardless of the product specs that were in place at the time of its creation, our CG artists are working with the most up-to date model specifications without needing to make retroactive updates to the product. Eliminating this type of maintenance work is key in making sure that we can get the most efficiency out of each asset and deliverable we create.